Not all scan abutments are the same!

We are constantly looking for better, safer and more efficient solutions for our patients. In implant dentistry, something as simple as the choice of intraoral scan abutments can make a big difference in the outcome of the finished product. In this article, we will review the reasons why titanium scan abutments are superior to scan abutments made of PEEK or PEEK with titanium coupling.

First and foremost, the titanium design is superior in durability and stability. Titanium is known for its strength and resistance to wear and tear, making it a better option for use in the oral environment. For example, if we look at DESS intraoral scan abutments, these are made of Titanium Grade V, and can be reused hundreds of times. The new bright variants are also coated with ZrN (Zirconium Nitride) which increases the strength and thus should increase the longevity. According to DESS, this also reduces the glitter effect during scanning.

PEEK scan abutments, on the other hand, are made of a thermoplastic polymer that can easily be damaged or warped over time, leading to problems with accuracy and long-term stability. It is usually recommended to use PEEK scan abutments as a disposable item to ensure that it does not lead to any error. In addition, titanium scan abutments offer greater accuracy and reliability in the scanning process itself.

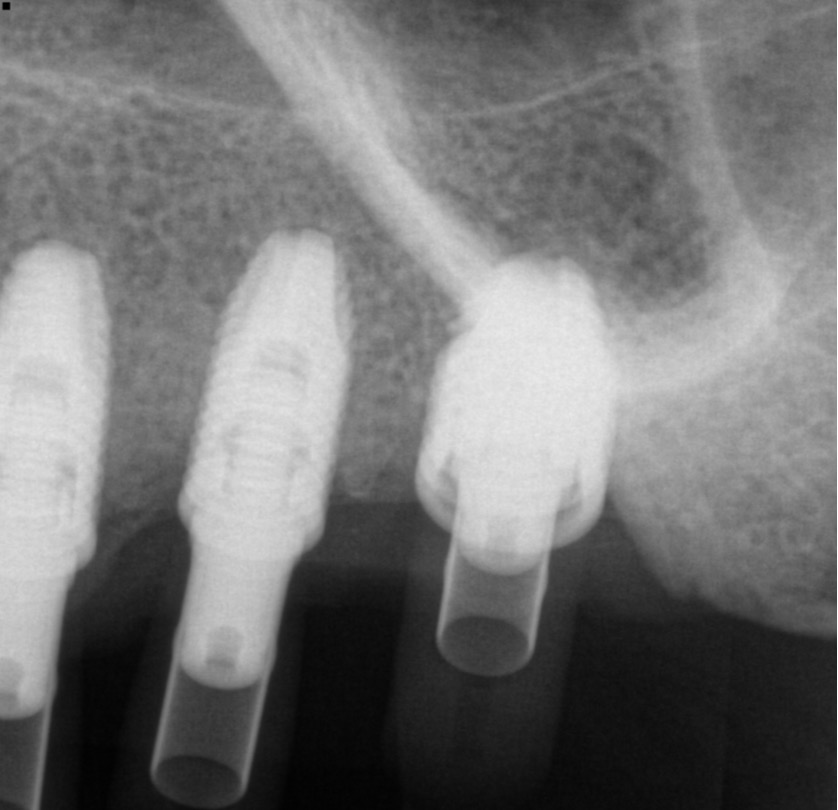

Titanium is more radio-opaque than PEEK, which allows better control via X-ray whether the abutment is correctly seated on the implant. This results in a more accurate and detailed scan, which is crucial to ensure proper placement and fit of the final construct. With a scan abutment partially or fully in PEEK, which is largely radiolucent, you are working a bit blindly hoping that it is in place and that the PEEK part has not dropped from the coupling, which we have often accidentally done in the past and got crowns that do not fit.

Another advantage of titanium scan abutments is their compatibility with a wider range of implant systems. The DESS portfolio, for example, currently covers 32 different implant systems and, with the different sizes, more than 100 available connections. This enables a variety of implant systems from a single supplier. The absence of screw holes also increases precision as the risk of distortion around the screw hole is completely eliminated.

From our own experience, we have also seen everything that can go wrong when using scan abutments in PEEK: worn connections, causing crowns to be easily rotated or end up completely wrong, height problems, loosening between the titanium interface and the PEEK body, resulting in crowns that do not go down, and many more problems.

In summary, the use of titanium scan abutments offers many advantages over those made of PEEK. These advantages include greater durability and stability, increased accuracy and reliability of the scanning process and compatibility with a wider range of implant systems. For these reasons, titanium scan abutments are a superior choice for both dental laboratories and dentists seeking the best possible outcome for their patients.

As a technician, I have no vested interest in DESS or their dealers, the only purpose of this article is to share my experience and make things easier for everyone in the digital world. In this particular case, I chose to expose a manufacturer who, like me, believes in high quality, reliability of delivery and the belief that only ‘the best’ is good enough. Of course, there are other manufacturers who make scan abutments out of titanium and even these are probably far better than PEEK.

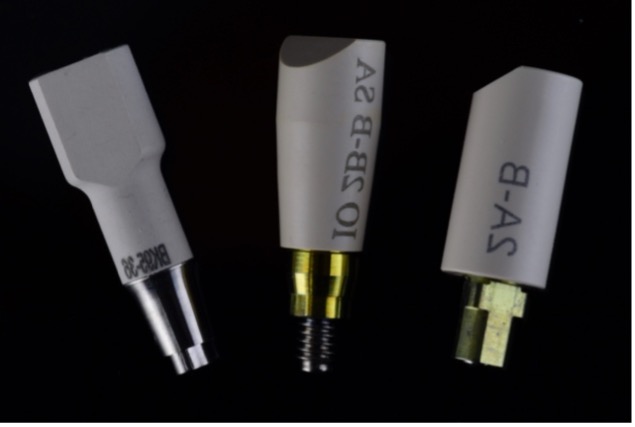

Examples of various scan abutments in PEEK and PEEK combined with titanium that will sooner or later lead to problems.

PEEK scan abutment on X-ray - how do we know it's down, and, are we irradiating the patient unnecessarily?

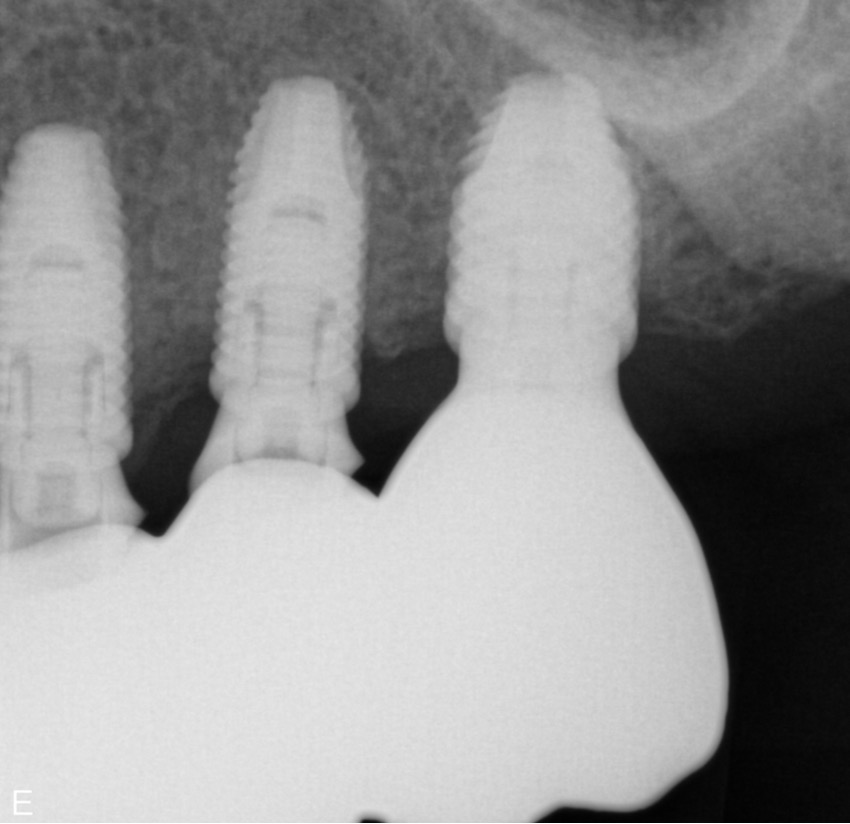

The same patient who later received a bridge that did not fit due to the PEEK part detached from the titanium coupling and constituted a height difference in the design.

DESS new scan abutments are also coated with ZrN which, according to DESS, reduces glitter effects during scanning and is clearly visible on X-rays.

Source: text and pictures Przemek Seweryniak, CDT

Cosmodent AB

www.cosmodent.se