DESS® New Flat Seat Screw

DESS® Flat Seat Screw: The Ultimate Solution for Full Arch Restorations

In the dynamic world of implant dentistry, continual innovations are revolutionising prosthetic restorations. These advancements not only streamline procedures but also significantly enhance the quality of life for patients by improving the functionality and comfort of their prosthetic solutions.

One notable shift is the growing adoption of Direct on Multi-Unit (MUA) techniques, which eliminate the need for a Ti-Base in certain prosthetic scenarios. This method represents a departure from conventional practices, favouring streamlined procedures that could lead to more effective results.

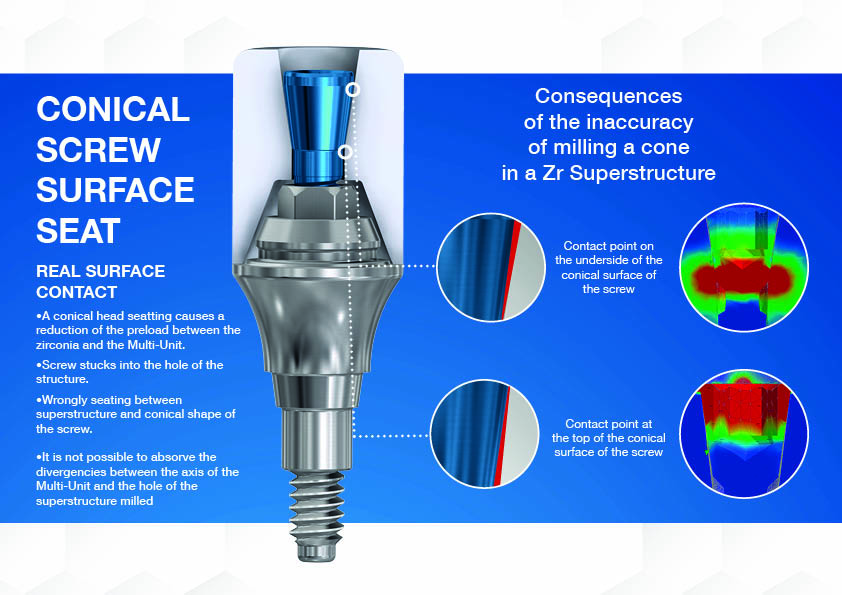

Challenges with Conical Screws: Rosen Screw, Powerball Screw, Vortex Screw

Several manufacturers have responded to this trend by developing unique screws tailored for direct on MUA applications, such as the Rosen Screw, Powerball Screw, and Vortex Screw. Despite their differences, these products share a common design element: a conical screw base intended to prevent loosening.

However, the inherent design of conical screws can introduce challenges. Specifically, the alignment within the MUA connection geometry often isn't perfect due to the multiple connections involved.

This misalignment can cause mechanical instability and impact the longevity of the implant-supported structures. The resulting stress could potentially lead to fractures in weaker screws or damage to the prosthesis if it bears the brunt of the force.

Conical Screws Limitations

Through rigorous testing, our engineering team has identified several drawbacks of conical screws, including:

• Reduced preload between the zirconia and MUA.

• Dependence on the precision of the milling machine for surface contact.

• Unpredictable final screw seating height, leading to potential collision issues and early screw loosening.

• Misalignment between the zirconia axis and the MUA.

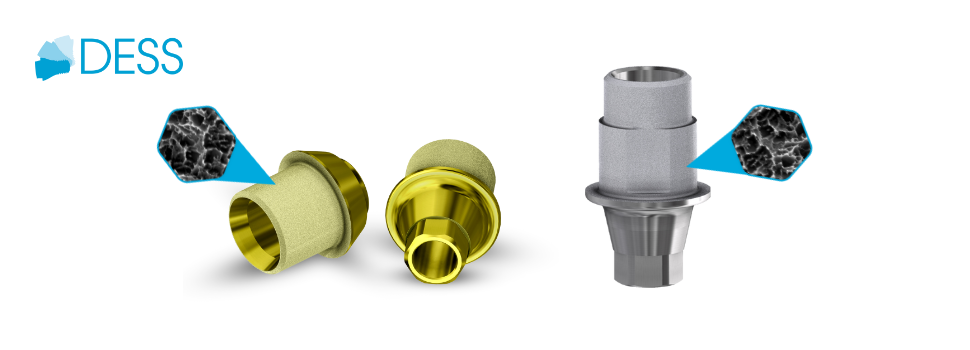

DESS® Solution: The Flat Seat Screw

To overcome all the issues caused by conical screws, DESS® has developed the FLAT SEAT SCREW, a new solution for direct on MUA applications.

Advantages of DESS® Flat Seat Screw

• Increased preload force ensures a secure connection between the full arch and MUA.

• Accommodates discrepancies in screw hole milling.

• Provides a consistent and reliable surface contact area, minimising the impact of manufacturing deviations.

• The flat seat enhances control over screw positioning and tightness.

• Allows for self-centering of the screw in alignment with the MUA axis, thanks to its adaptive seating.

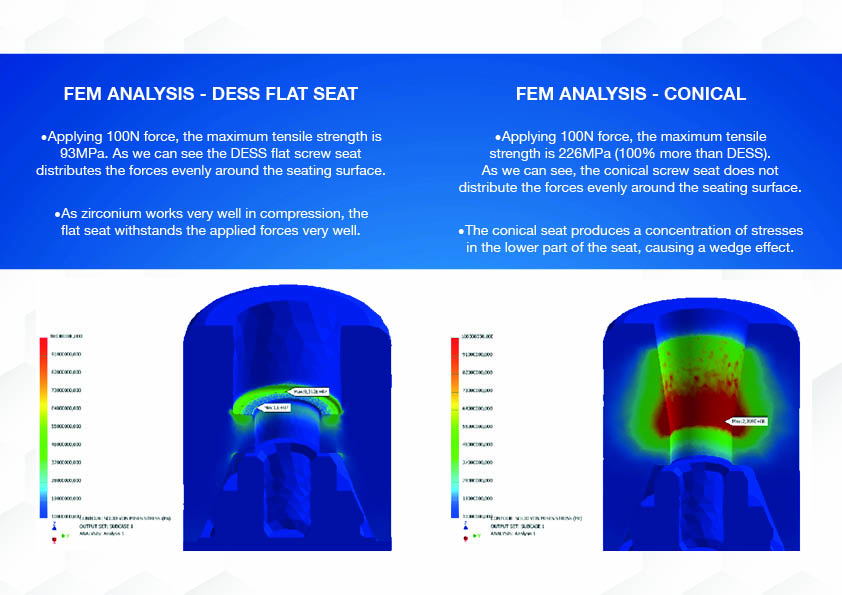

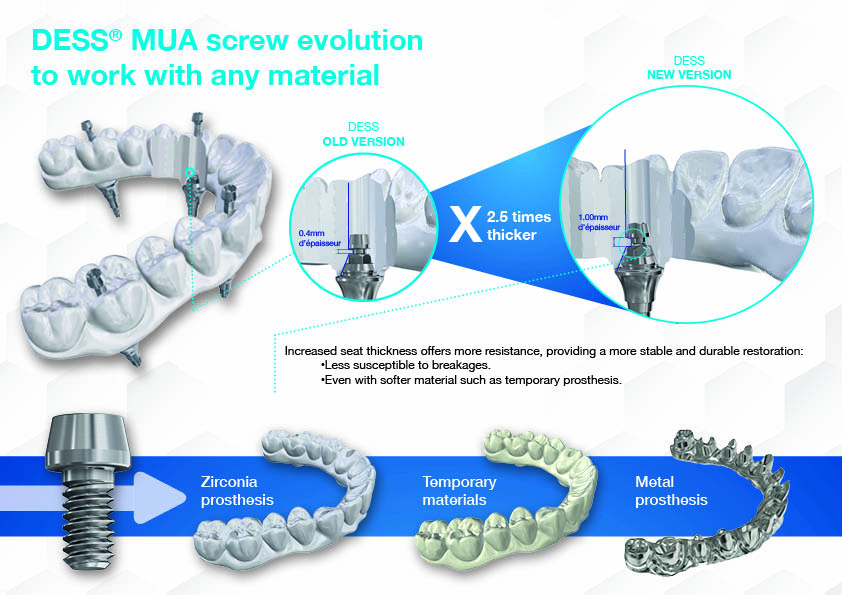

Enhanced Performance and Durability

Our comparative tests have shown that the DESS® Flat Seat Screw achieves superior preload, distributing forces more evenly across the seating surface. This leads to a more robust and durable prosthetic restoration, less prone to damage even when using softer materials.

Innovative Torx Socket Design

Furthermore, the new DESS® Screw features a Torx socket design. This innovation, combined with the DESS® libraries, supports angled screw channels up to 25°, enhancing the structural integrity and aesthetic quality of the final prosthetic.

In summary, the DESS® Flat Seat Screw represents a significant advancement in the field of implant dentistry, providing a more stable, reliable, and aesthetically enhanced solution for direct on MUA restorations.