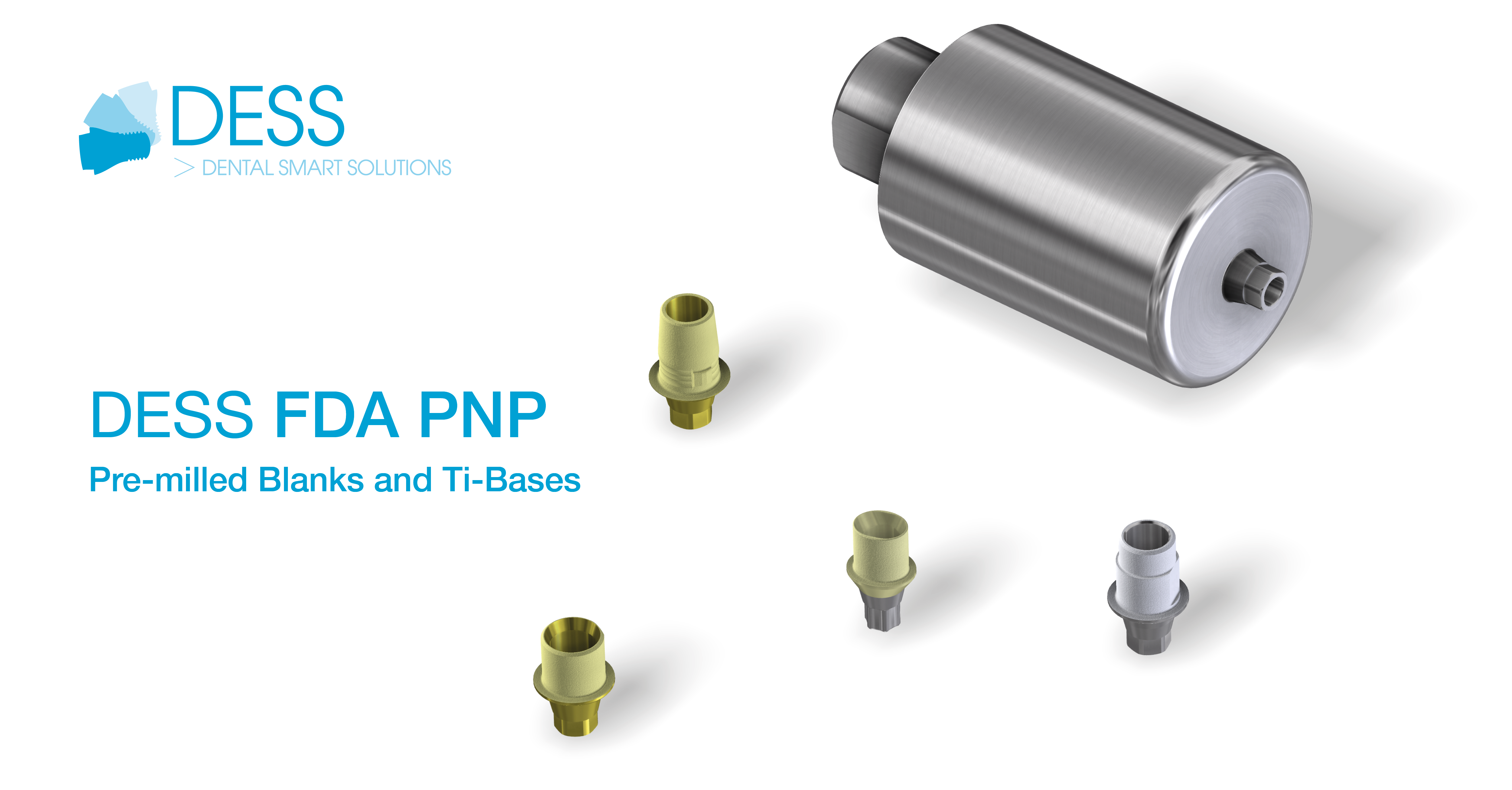

DESS Dental receives the exclusive PNP FDA accreditation for our Blanks and Ti-Bases

Dental laboratories and milling centers without FDA certification can become FDA compliant by using DESS® Blanks and Ti-Bases.

DESS® Blanks and Ti-Bases are now PNP FDA accredited, upgrading the FDA accreditation for these products achieved in 2017. This allows dental laboratories and milling centers to comply with FDA regulations without being FDA registered or having a QMS in place by using DESS® Blanks and Ti-Bases and following DESS® Digital Soutions IFU.

The dental laboratory industry is increasingly utilizing CAD/CAM automated manufacturing techniques. Meanwhile, the FDA is reviewing regulatory requirements for these processes and making changes, such as the modification of the 510(k) requirements for Ti blanks and Ti bases used in dental implant abutments. Both these abutments fall under Product Code NHA and are subject to the same FDA regulations. The FDA requires that manufacturers, including dental laboratories and milling centers, become "validated milling centers" and implement manufacturing procedures in line with Quality System regulations.

Furthermore, the "establishment exemption" for CAD/CAM procedures in dental laboratories is being phased out, meaning that more laboratories will need to register with the FDA and allow for FDA audits.

This scenario has raised fears of a potential closure of milling centers and dental laboratories which are not FDA accredited. Thanks to DESS® new FDA accredited Digital Dentistry Workflow, any non-FDA certified milling centers and dental laboratories have the opportunity to remain operational since, by using DESS® Digital Dentistry Workflow products and following our Digital Solutions IFU, they do not need to obtain the pertinent FDA certification.

This is hugely positive news for the sector as our certification will help many dental laboratories and milling centers to stay in business. Additionally, we are pioneers in the industry in obtaining this accreditation therefore we are offering a very exclusive value for businesses.

DESS® is fully aware that performing a save practice that contributes to the patient’s health and safety is a number one priority for milling centers and dental laboratories, reason why we can assure that DESS® FDA 510(k) certification guarantees that any milling center or dental laboratory that follows our Digital Dentistry Workflow with our products, is 100% compliant with FDA policies therefore in accordance with health and safety guidelines.

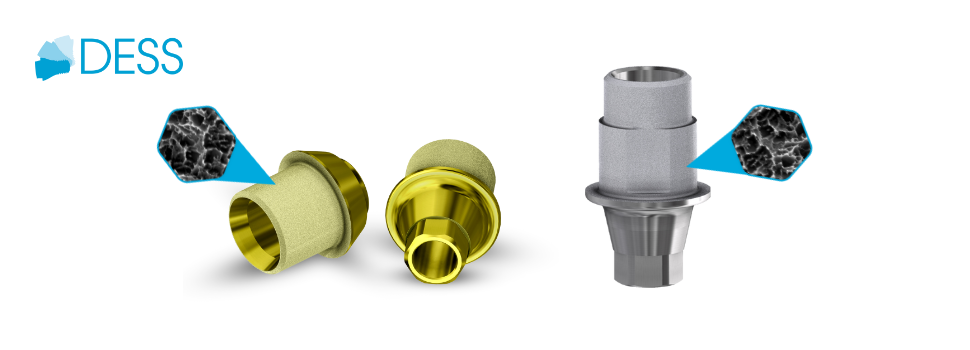

The range of DESS® products covered by DESS® FDA PNP accreditation is:

Furthermore, DESS® FDA approved Digital Dentistry Workflow integrates the following components:

- 18 Implant System Compatibilities that include 56 implant platforms.

Astra Tech EV, Astra Tech OsseoSpeedTM, BioHorizons, Biomet 3i Certain®, Biomet 3i OSSEOTITE®, Camlog, Friadent XiVE, MegaGen AnyRidge, Neodent Grand Morse, NobelActive®, NobelReplace® / Nobel Parallel Conical, NobelReplace® Trilobe, Nobel Branemark System®, Osstem TS, Straumann® BLX, Straumann® Bone Level, Straumann® Tissue Level, Zimmer Screw-Vent® / Tapered Screw-Vent®.

- Scan files from intraoral and desktop scan abutments.

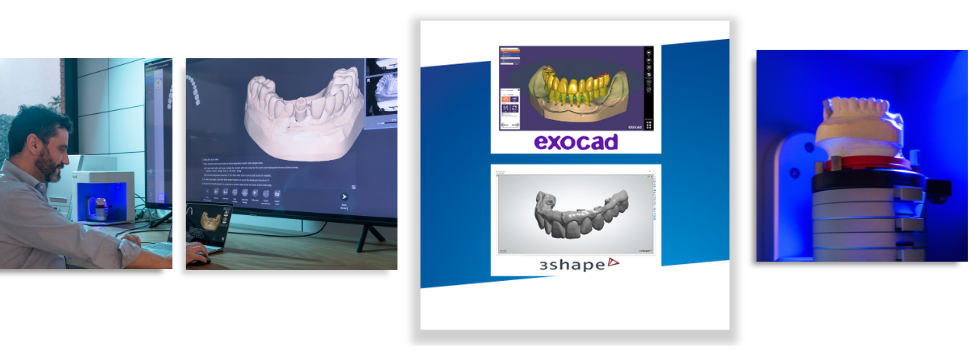

- CAD / CAM software.

- Ceramic material.

- Titanium material.

- Milling machine.

- Associated tooling and accessories.

(*) Read the Digital Solutions Summary to know the present conditions of the workflow implied. You can also access the Digital Solutions IFU. The workflow elements will be always expanded to make sure you are up to date.